ELANG

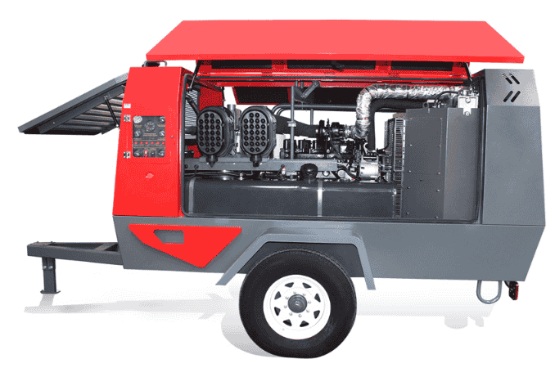

Portable diesel powered air compressors are widely used in various industries, including but not limited to the following:

Construction and Building Industry: Diesel portable air compressors are used to power pneumatic tools such as drilling machines, spray guns, and impact wrenches at construction sites.

Mining and Excavation Industry: Diesel portable air compressors supply compressed air to underground mining equipment and tools used by miners in mining operations.

Sandblasting and Drilling operations: Elang diesel portable air compressors are ideal for sandblasting operations and are commonly used, even as core equipment, in borewell operations (especially air drilling, down-the-hole hammer drilling and as auxiliary power). Its self-powered and mobile nature gives it an irreplaceable advantage in field, unpowered or mobile construction scenarios.

Road Maintenance and Repair: Diesel portable air compressors provide compressed air for equipment like excavators, road cutters, as well as for inflating road signs and road repair tools.

Leak Repair and Emergency Maintenance: Diesel portable air compressors are employed for emergency tasks such as inflating tires, operating circuit breakers, and other urgent repair tasks.

Advantages:

1.High quality and reliability: Less spare parts, strong and durable in all conditions, long life, repair period of 40 to 80 thousand hours.

2.Simple, easy to use and maintain: highly effective, satisfactory results.

3.Well balanced and high power: running smoothly and at high speed, with technology dedicated to portable air compressors, small in size, light in weight, longer life;

4.Adaptable in all hardships and strong atmospheres: With the obligatory gas transmission characteristic, the flow volume is almost free from the effect of exhaust pressure, in a wide range of speed to maintain high efficiency.

5.Outdoor work: Elang Diesel-powered air compressor can be taken anywhere, which is their most significant benefit over traditional compressors. It is widely used in outdoor, construction sites, and emergency maintenance situations.

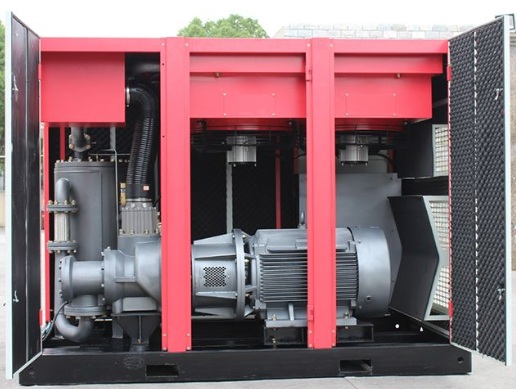

Medium Pressures Double Screw Air Compressor is a kind of oil-injected double screw air compressor with screw air end of high quality medium pressure single-stage or two-stage type. Reliable perfomance, excellent quality, enviromental protection and energy-saving. Widely applied to the industries of mine projects, medical, food, electronics, chemical plant, mechanical and so on.

Perfect screw air end design parameter, accurate calculation of heat balance and linear expansion coefficient, high volume efficiency and advanced process flow. Superior product, sophisticated processing and manufacturing, and precision coordination, that can reach high efficiency and best compression ratio. The thrust bearing and radial bearing with better anti-abrasion function have more strong axial carrying capacity and stable running performance. The new inter-stage, cooling system make the compression ratio between two-stage compression higher, improve compressor efficiency, lower power consumption, save energy and protect environment, The wide application of unique sealing technology in the screw air end make reliability more higher and maintenance more convenient.

Powerful motor with SKF precision bearings and F insulation grade is of high protection motor, which is safe and reliable, high energy efficiency. Motor rich capacity can bear continuous full-load operation without failure under all kinds of bad weather condition.

With excellent control system and ultra-strong safety protection function, the micro-computer controller of screw air compressor is the new generation high technology product developed by ELANG. It has the functions of controlling, communicating, ultra-strong safety protection, remote control and multi-computer control.

1. Large displacement: Displacement 10% higher than ordinary piston compressor.

2. Energy-saving: Compared with piston air compressor, this series of models for the new national standard two energy efficiency products, excellent energy saving.

3. Easy to operate: 24 hours unattended all day work, free load automatically start, full load automatically shut down.

4. Strong stability: Under long time working, displacement and pressure stable, no crash phenomenon, low failure rate.